ESCROW.COM Removes the Gamble and Helps Protect Your Investment

Heat Safety Rule Is Moving — Put a Field-Ready Plan in Place Today

A simple, inspector‑friendly framework you can roll out in one toolbox talk.

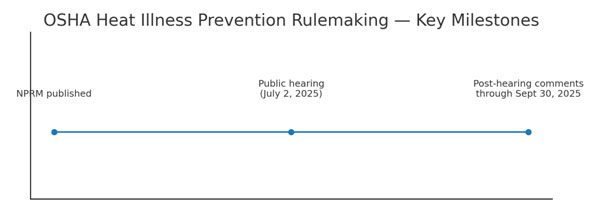

Regulators have advanced a national heat illness prevention rule, and regardless of the final text, the expectations are already clear: hydrate crews, plan work/rest, train supervisors, and document what you’re doing. You don’t need a 40‑page binder to be compliant‑ready. You need a practical routine your foremen can run daily.

Figure 4. OSHA Heat Illness Prevention Rulemaking — Key milestones in 2025.

Use this field‑ready model and paste it into your job binder:

1) Daily heat briefing (2 minutes).

• Foreman checks the day’s forecast and heat index before the morning stretch.

• Announce the plan: hydration, shade location, and targeted break times (e.g., 15 minutes each hour during peak).

• Identify who is new or returning after time off; those workers get lighter duty for acclimatization.

2) Hydration and shade.

• Water and electrolyte mix are available at marked coolers within a 100‑foot walk of the active work area.

• Shade structure or conditioned space is set and labeled “Cool‑Down Area.”

3) Work/rest cycles and PPE adjustments.

• For heavy work in high heat, shorten continuous exertion and add micro‑breaks in shade.

• Encourage looser‑fit, breathable clothing; avoid dark colors where possible.

4) Training and buddy checks.

• Supervisors and leads can identify early signs (cramps, dizziness, headache, confusion) and know the emergency steps.

• Crews pair up and check each other at the top of each hour in peak heat.

5) Incident response.

• If a worker shows symptoms, move them to shade, start active cooling, call EMS if symptoms escalates, and document the event.

6) Documentation (keep it simple).

• A one‑page daily checklist: forecast/heat index, cool‑down set, water stocked, acclimatization noted, breaks taken, any incidents. Take a photo of the checklist and save it to the job folder.

This framework satisfies what most inspectors now expect to see: a plan, daily execution, training, and records. It also keeps your crew safer and your project on schedule by preventing avoidable heat‑related delays.

How many times have you stepped into a country club restroom or upscale dining space and felt that quiet, unmistakable sense of refinement? The air seems softer, the lighting warmer, even the water flows differently. Learn more…

Part of Construction Digital Toolbox brought to you by Contractors Junction. This Publication includes a Project Kickoff Checklist. Learn more…

Part of Construction Digital Toolbox brought to you by Contractors Junction. This Publication includes a FREE “Scope of Work” print and save PDF. Learn more…

Part of Construction Digital Toolbox brought to you by Contractors Junction. This Publication includes a FREE print and save “Change Order PDF“. Learn more…

The trap happens when a great operator assumes the same drive and focus that made them efficient in the field will automatically translate to running a company. It rarely does. The job shifts from producing work to managing people and resources, and those who fail to make that shift often end up overworked, underpaid, and burned out. Learn more…

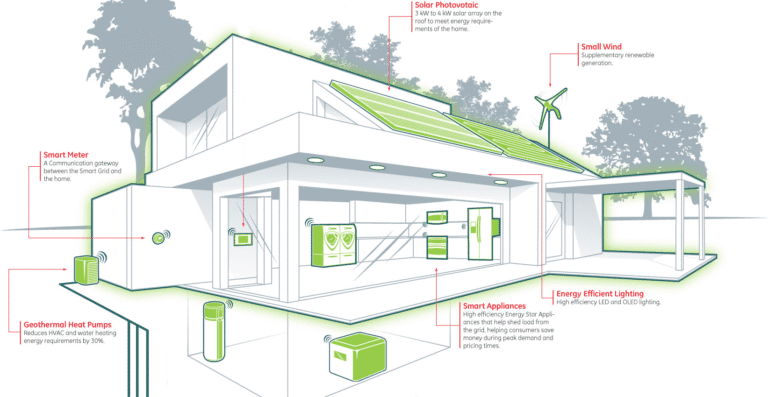

Sustainability isn’t a passing trend—it’s reshaping how the construction industry operates. Contractors who adapt now will find themselves ahead of the curve as clients, architects, and local governments push for energy-efficient, environmentally responsible projects. Learn more…

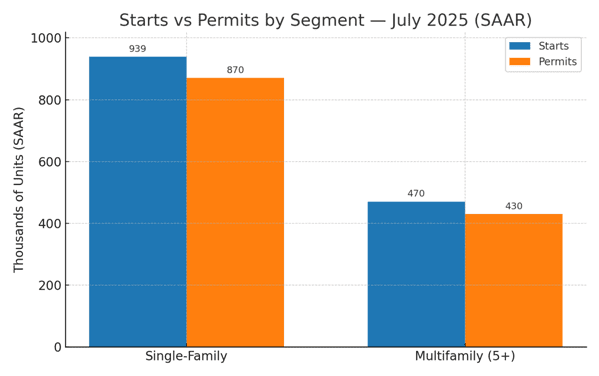

The latest federal housing data delivered a mixed message that matters directly to your schedule and cash flow: housing starts ticked up, while building permits slipped. PDF”. Learn more…

Regulators have advanced a national heat illness prevention rule, and regardless of the final text, the expectations are already clear: hydrate crews, plan work/rest, train supervisors, and document what you’re doing. Learn more…

Affiliate Disclaimer: This site uses affiliate links. We may earn a commission when you click.